Product classification

Contact Information

Address:

East of Dongzhuangtou Village, Weijiazhuang Town, Longyao County, Xingtai City, Hebei Province

Mobile:

+86-18731979232

E-mail:

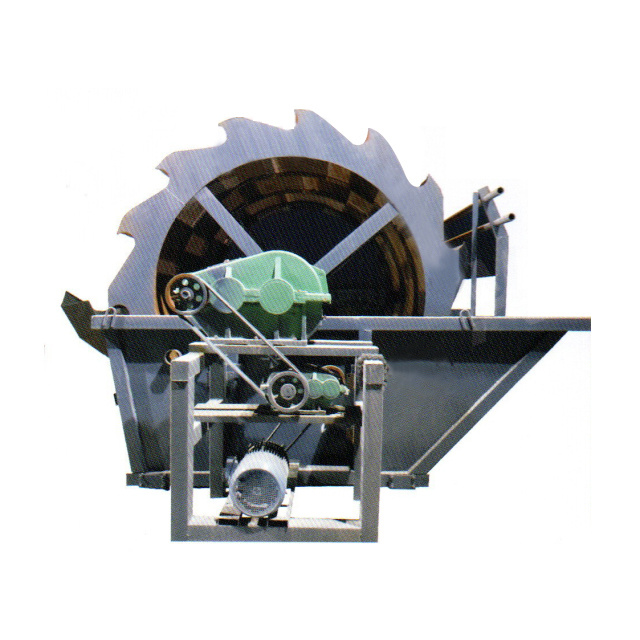

Forced push discharge sand sieve machine (customizable)

Main products are electric forklift, electric stacker, electric truck, electric lift platform, semi-electric stacker, manual truck, manual stacker and other material handling equipment.

- Product Description

-

USES AND FEATURES

This sand screening machine is a high efficiency and low fault model derived from the summary and troubleshooting of various problems encountered in the use of various styles and forms of sand screening machines on the market.

Its structure and advantages are as follows

1. The conveyor adopts intensive three-group roller design, which runs more smoothly and the belt is not easy to deviate.

2. The discharging mode of the upper hopper adopts the crank connecting rod structure to drive the pushing plate to force the discharging. Dry and wet materials are not affected, greatly improving the fluency of the discharge, and the discharge efficiency is more than twice that of the ordinary sand sieving machine (the pushing speed can be adjusted).

3. The diameter of the drum screen cage is increased and lengthened, so that the materials can be screened out more easily in the drum, so as to avoid fine particles from being screened out of the waste pile due to the short screen dragon and other reasons. The drive reducer is rear-mounted, the screen dragon will not derail, and the screen dragon shaft will not pass through the hopper, thus greatly increasing the discharge rate and increasing efficiency.

4. This machine can be equipped with anti-blocking brush to dredge the blocked mesh in time to greatly improve the screening efficiency.

Main technical parameters

Model 80T forced push discharge sand screen machine Exterior dimension 11300x2050x3200mm Hopper 3800mx1700m Motor power 7.5 5.5 3 kW Conveyor belt 22000-1000mm Conveying height 4000mm Screen Size 3500-1200m Mesh size 1.0 (replaceable) Work efficiency 140 cubic meters per hour -180 cubic meters per hour

Key words:

Get Quote